Frore Systems caused something of a stir back in 2023 with the announcement of its fanless AirJet cooler. It's a solid-state cooling solution that uses an innovative ultrasonic vibrating membrane to move air in a much smaller package than a traditional fan setup. While it was touted as the potential next step in cooling design, at least for small form factors, I've had my concerns about the AirJet device. The lack of adoption and similar lack of significant media coverage since then isn't a super positive sign.

At Computex 2024 I got the chance to get hands-on with the latest version, the Frore AirJet Mini Slim. I also had the opportunity to chat to Frore Systems CEO, Dr. Seshu Madhavapeddy, about scalability, use-cases, and exactly what sort of performance the new models can deliver.

Surrounded by various devices jury-rigged with AirJet Minis, one of my first questions was about noise. A pet theory, perhaps, but an early assumption I'd made about the lack of adoption was how much noise a jet of air would make, and whether a high pitched whine or similar issue might be holding it back. I asked Dr Madhavapeddy if I could hear one, up close, moving air at full-tilt.

“Of course”, he replies. “You're surrounded by them right now.”

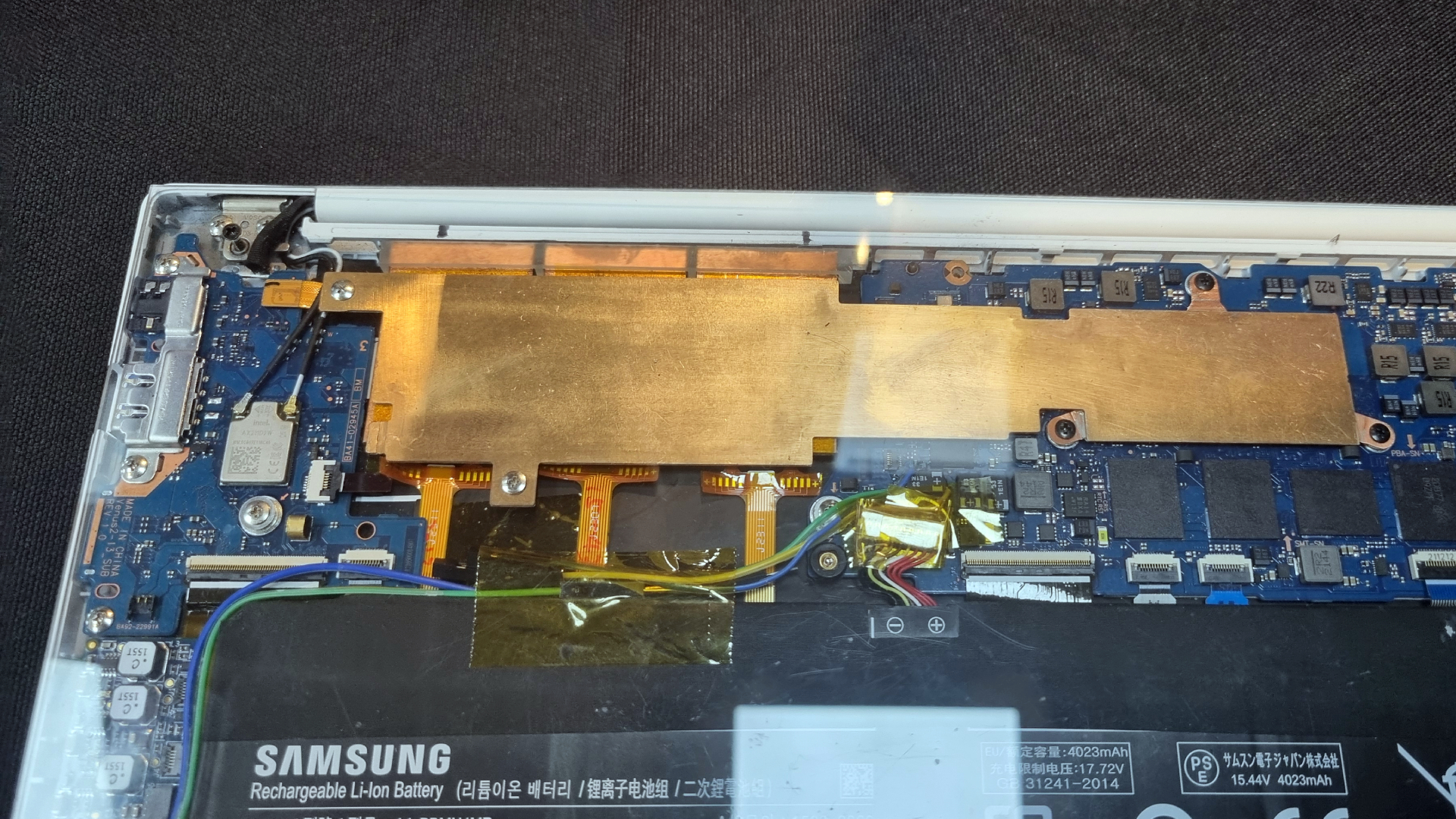

While the various Macbook Airs, iPhones and similarly thin devices around me were wearing transparent cases to show the AirJets inside, I'd assumed they were idling, given the lack of fan noise in the room. I picked a laptop up and held it to my ear, and sure enough, it was pushing a decent amount of hot air while running a benchmark—and the noise was only audible a few inches away. Even then? Surprisingly quiet.

Granted, this was in a conference room at the Nangang Exhibition centre, so background noise was absolutely a factor. However, with no distinct whine or noisy whooshing of air from even a close distance, the AirJets I saw were running much more quietly than I'd expect at max capacity.

Beyond that, the benchmarking graphs show significantly better performance results for chips fitted with AirJets compared to models featuring traditional cooling systems, or passive solutions. So if the performance is impressive and my personal noise theory quashed, why haven't we seen the AirJet feature in more devices?

We’re not bound by the limitations of mechanical devices for how we can make it more and more powerful

“Doing something as disruptive as we are doing—basically we are creating the entire supply chain, and the manufacturing line for this—this is a very complex product that we've built using entirely new materials, and manufacturing processes,” explains Dr. Madhavapeddy.

“So, you know, I would urge you to be a little patient.”

Fair enough. However, the products I was shown looked—and felt—like production units, not prototypes, and the room was full of them. How many are Frore ready to produce, I asked?

“Millions,” Madhavapeddy replies, with a grin.

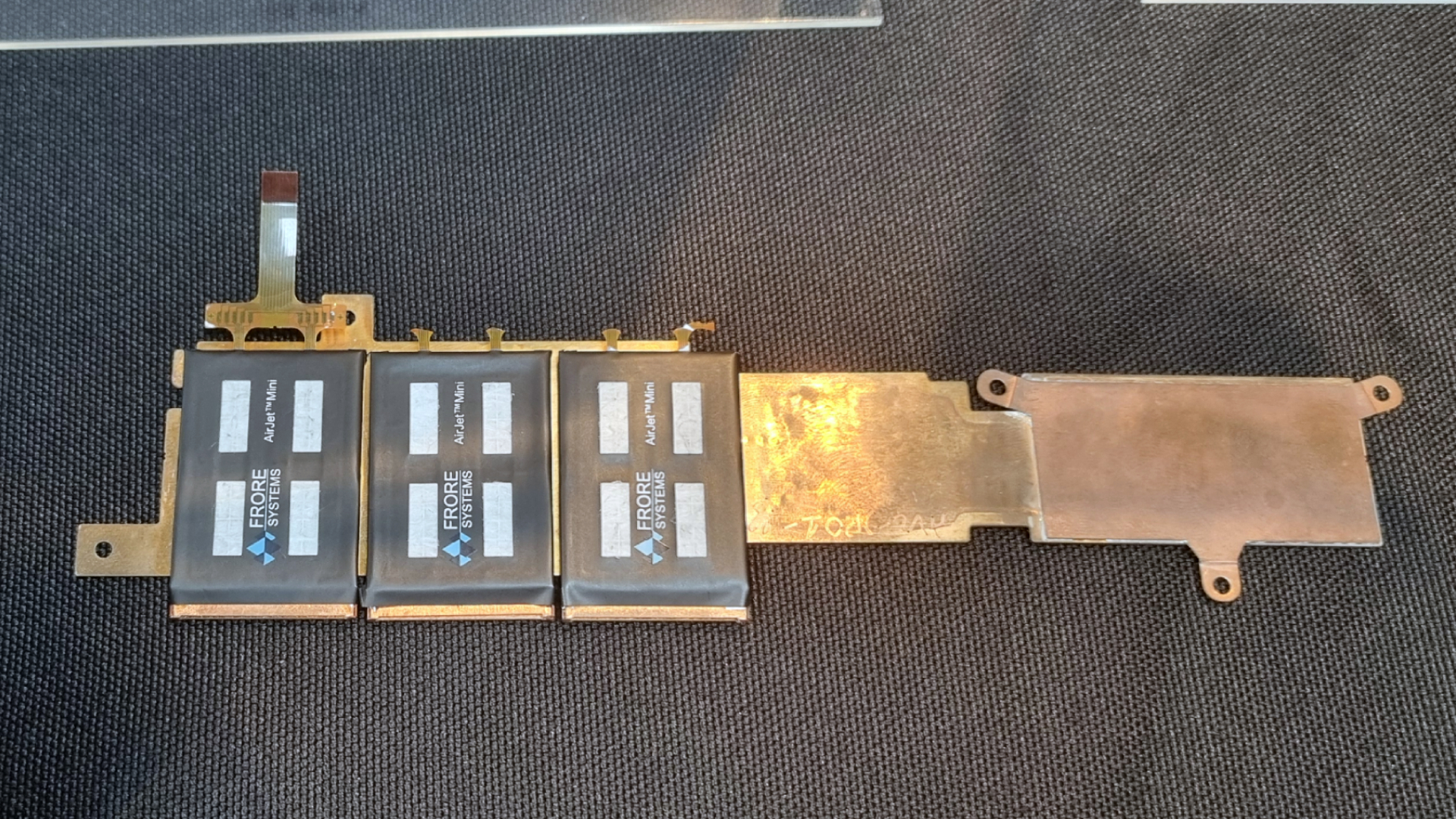

Holding the AirJet Mini Slim in my hands and looking through media detailing its internal mechanism, it isn't difficult to see why such a small unit with such a radical approach to moving air would take time to scale for mass production.

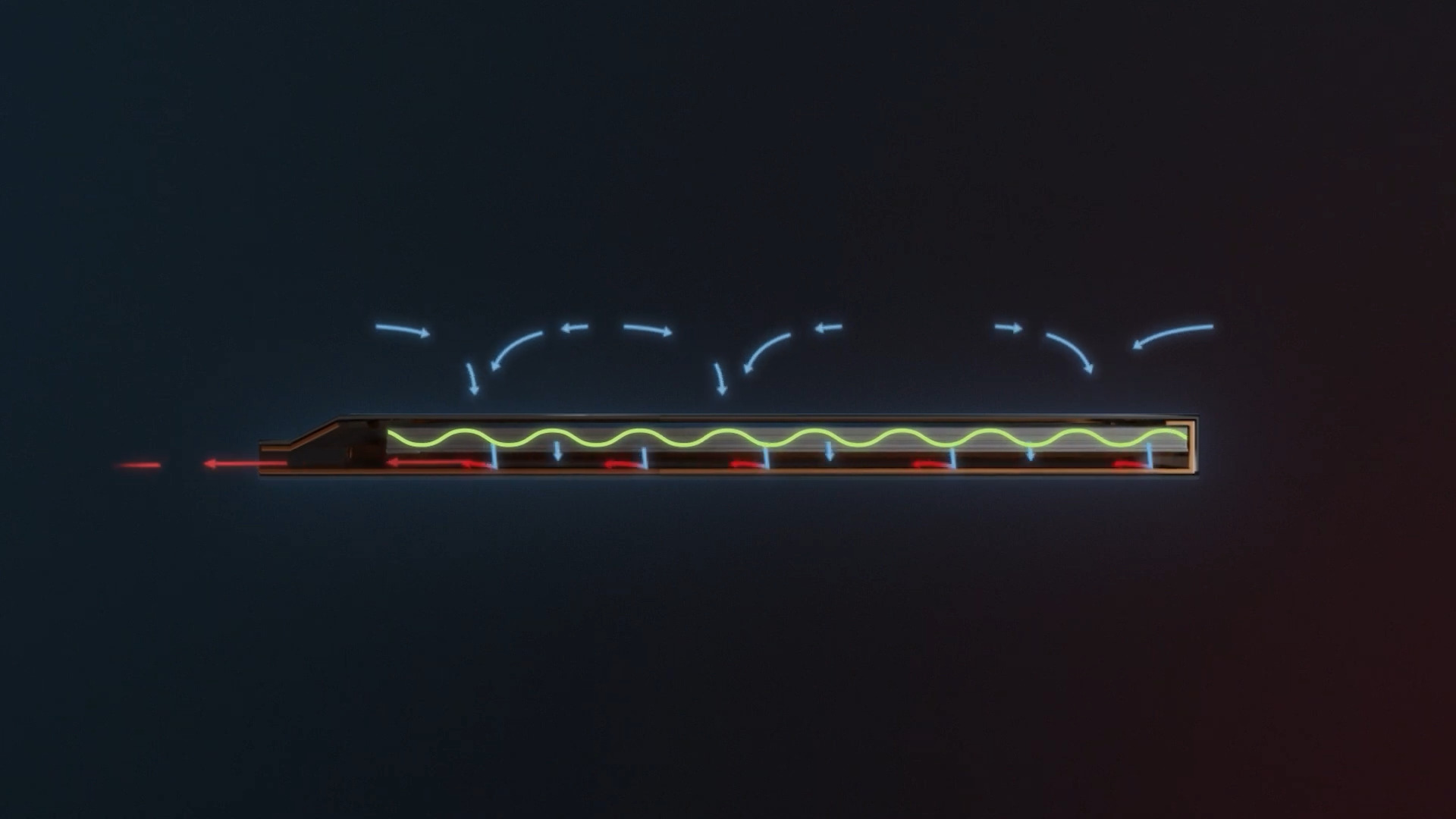

The internal piezoelectric membrane vibrates at 24 kHz, and pulls air in from the top of the device, disrupting the “boundary layer” of hot air above the chip being cooled underneath it, before firing it out of a thin vent at one end. This mechanism is said to be key to the AirJets efficiency in such a small device, compared to a similarly-sized conventional fan.

That fast moving membrane, however, strikes as an easy point of failure. I asked if Frore had conducted any long-term durability testing, and the expected lifespan of a single unit:

“We've gone through numerous reliability tests,” says Madhavapeddy. “We have been able to confirm that it would last for about 10,000 hours of continuous operation. That should be about five years in a typical use case scenario.”

While fans die all the time, I'd say it'd be reasonable to expect a conventional fan to last for over five years of operation. A Noctua fan is rated at over 150,000 hours, for example. Still, with the AirJet acting as a single, self-contained unit—and providing a device using one could be opened easily—replacing one when it fails doesn't seem like it'd be too taxing of a task, and potentially easier than a conventional fan/heatsink combo in a regular laptop.

Looking around the room, most of the demonstration devices had one thing in common: very thin, very light, and difficult to design around conventional fans. Given the claimed efficiency of the device, I wondered out loud about eventually seeing several strapped to a desktop CPU. At this suggestion, Dr Madhavapeddy seems to slightly recoil:

“For desktops, I think right now, with this generation, we could help with spot cooling. For Gen 5 SSDs, if your main fan-based cooling system is taking care of the CPU cooling, you can put one of these on top of a Gen 5 NVMe controller, and get relief.”

So, it seems that as things currently stand, even several AirJets don't seem capable of handling something like a high-powered modern desktop CPU any better than a good old-fashioned heatsink and fan. Still, the suggestion of a thin, efficient Gen 5 SSD cooler compared to some of the sizeable models I saw at this years show seems like a tangible use case for the tech as it exists today.

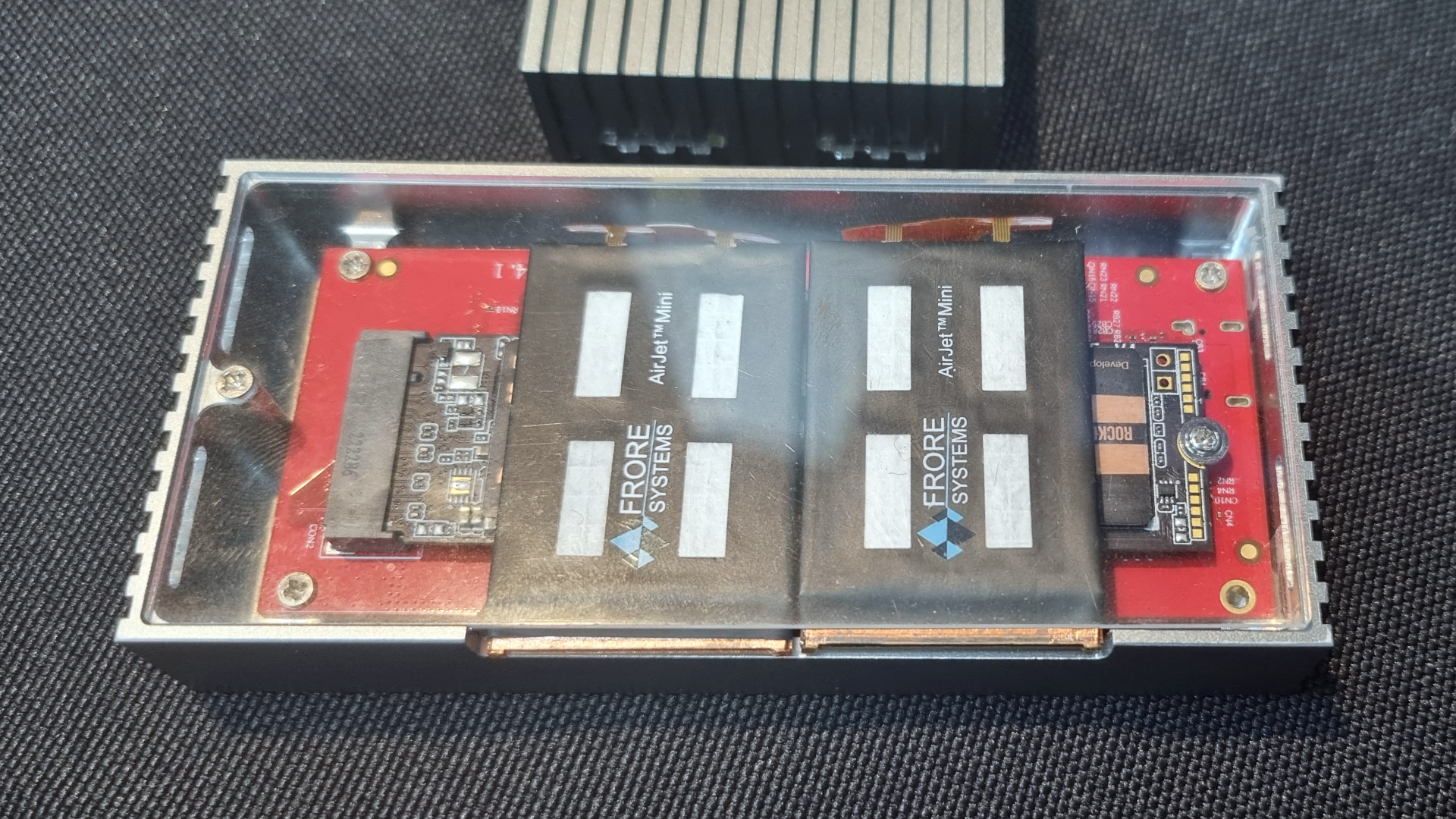

To this point, I was shown an external SSD with two AirJet Minis integrated into the chassis. A passively cooled version dropped to a 1,061.77 MB/s write speed over sustained usage, whereas the AirJet-cooled sample was shown to maintain a consistent 3,153.98 MB/s rate.

Roughly three times the performance is not to be sniffed at, although the form factor could do with some work. The prototype I was shown had the output vents situated on the side, meaning it was blowing uncomfortably hot air right where you'd put your hand to pick it up. A production model was suggested with the vents on the end of the device, although I think it'd take some getting used to an external drive venting large amounts of hot air, no matter how quietly or efficiently.

So then, the million dollar question: Given the inevitable R&D and manufacturing setup costs, how much does an AirJet Mini eventually cost per unit?

“It's reasonable,” says Dr Madhavapeddy. But reasonable in comparison to the costs of manufacturing a good fan?

we have several levers…to significantly improve the thermal dissipation capability of the chip

“No. No it's not. But reasonable compared to the overall cost of the product that you purchase as a consumer. We fit into the structure of the costs that typically can be borne by anybody who's making a device of this nature.

“But if we compare head to head with a fan, we will be more expensive. [The price] would come down with scale. It will also come down because our second generation, third generation are going to be more high performance.

“We wouldn't expect the cost to go up at the same rate as the performance is going up,” Madhavapeddy continues. “So the performance, the cost per watt, will come down with subsequent generations. And also, in any given generation, the cost comes down with volume.”

Speaking of future developments, the company has a credo that, on the surface, seems somewhat outlandish. It's called “Frore's Law”, a play on Moore's law, which in this case is the goal to double the thermal performance of the unit every two years.

“We're not bound by the limitations of mechanical devices for how we can make it more and more powerful,” says Madhavapeddy. “We could increase the performance by increasing the frequency of vibration, we can also increase the performance by increasing the amplitude (of the vibrations).

“So we have several levers that we can continue to improve on to significantly improve the thermal dissipation capability of the chip”

That's an ambitious goal, and one that seems more than a little unfeasible. That being said, the units I was shown seem much more ready for prime-time than I was expecting. If they really can be scaled up in performance at that kind of a rate, it does seem like more adoption would follow.

While the AirJet Mini Slim might not be the solution for all cooling needs as it currently stands, what it does seem to do well is move significant amounts of air in form factors that are unsuitable for a traditional cooler.

You won't be seeing one in a desktop PC anytime soon, at least on something substantial like a GPU or CPU. But in ultra-slim laptops, tablets, phones and the like, or atop an SSD? The AirJet, at least in Mini Slim form, does seem like a product that's ready to go. Whether mass-adoption follows, however, we'll just have to be a little more patient to find out.