With the official launch of its new Core Ultra 300-series of processors going very well so far, Intel’s latest process node, 18A, appears to be a successful endeavour. We won’t know for certain until all the benchmarks come out, of course, but regardless of how good it is, Intel isn’t rushing to gear up its next-gen 14A foundries to push out mountains of wafers.

And that’s straight from the horse’s mouth, David Zinser (Intel’s chief financial officer) to be specific. In response to a query about concerns over not being aggressive enough in placing orders with suppliers like TSMC, during Intel’s conference call yesterday (transcript via Seeking Alpha), Zinser offered a reply that didn’t directly address the question but still made Intel’s position clear.

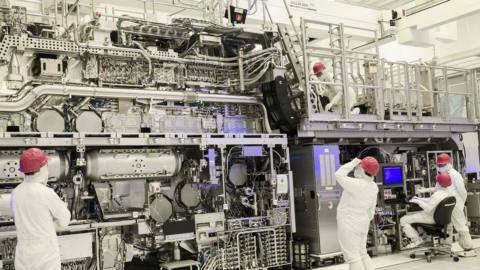

“We are aggressively getting tools on Intel 7, 10, Intel 3, 18A—that is happening. And we will be increasing our wafer starts as aggressively as possible on those nodes. What we’re holding back on is 14A because 14A is really linked to foundry customers, and it does not make sense to build out significant capacity there until we know that we have the customers that will accept that demand.”

The phrase ‘getting tools’ essentially refers to buying the necessary apparatus and supplies to churn out the millions of wafers that each process node foundry can do. With demand for chips at an all-time high, every wafer manufacturer will want to book supplies in advance, but with the competition doing the same, that’s where the ‘aggressive’ part comes into play.

However, that’s not what Intel is doing for 14A and for good reason. First of all, it’s not ready for mass production yet, but even if Intel went ahead and got prepped to max out the foundry’s capacity, there’s no guarantee that there will be the demand for the chips that those wafers ultimately produce.

Zinser is almost certainly referring to the uncertainty of how the consumer PC industry is going to fare in 2026 because of the AI-induced global memory supply gooey kablooie. DRAM and flash chips now all sport sky-high price tags and a dearth of availability, both of which are necessary for any PC.

In previous years, Intel would simply grind out as many wafers as possible, because it knew that it would have no problem selling processors. Fast forward to today, and OEMs and system integrators have probably already indicated that they’re not going to be placing anywhere near the same volume of orders as they previously did.

Intel’s 14A isn’t going anywhere, of course, and Zinser indicated in the conference call that the company has ‘different variants of 14A’ to offer, including the implementation of High NA lithography. Just don’t expect a glut of Nova Lake options when it eventually launches later this year.